At their core, Human-Machine Interface (HMI) technologies are “The hardware or software through which an operator interacts with a controller. An HMI can range from a physical control panel with buttons and indicator lights to an industrial PC with a color graphics display running dedicated HMI software.”

The Computer Security Resource Center defines HMI technologies as such. HMI technologies, while relatively “dated” to some, arguably remain relevant. In this week’s article, we will be discussing HMI technologies. More specifically, we will be discussing the types of technologies, applications, and benefits of HMI technologies.

Technologies

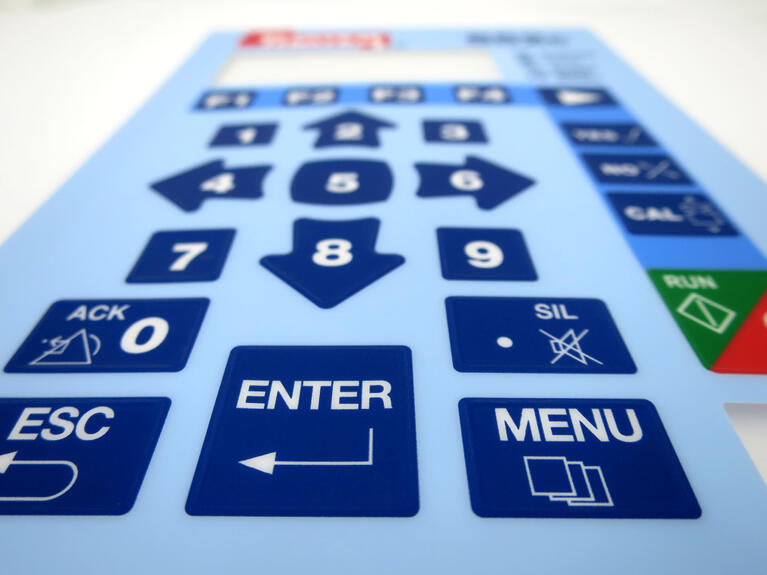

There exist two types of HMI technologies. The traditional forms of HMI technologies take the form of membrane switches. Membrane switches are essentially electrical switches made from a composite of plastics and specific metals.

The modern forms of HMI technologies take the form of touch screens and remote monitoring. While the former are fairly straightforward, the latter allow for the management of machines through remote devices. However, HMI technologies did not always take this form.

In fact, HMI technologies have progressed quite far since their first inception in the 1950s. Back then HMI technologies were built around batch processing models, utilising punch cards to input instructions. Thereafter, command line interface models were implemented, followed by graphical user interfaces, writes Britannica.

Applications

HMI technologies are especially relevant in five sectors: Industrial, automotive, energy, medical, and appliances. Grand View Research writes the following. “HMI terminals are significantly used in the manufacturing industry for automation for improvement of overall plant management by improving communication between user & machine, providing warning & alarms, and cost reduction…”

“Key end-use industries with heavy demand include food & beverages, oil & gas, and packaging. Increasing shale oil extraction significantly in North America may increase the need for industrial automation, thereby offering avenues for growth… In automobiles, usage of advanced technology has transformed the car dashboard layout to more flexible, dynamic, and adaptable design…”

The National Library of Medicine adds that HMI technologies can have other significant healthcare sector applications. Health monitors, medical diagnostics equipment, prosthetic and assistive devices are just a few applications of HMI technologies in the healthcare sector.

HMI technologies are also common in everyday appliances and is, in fact, one of its largest markets. Dishwashers, microwaves, and ovens all have HMI technologies embedded, as do remote controls, electric cookers, and electric locks.

Benefits

HMI technologies, more specifically membrane switches, are incredibly beneficial technologies. This is due to multiple reasons.

- HMI technologies, more specifically membrane switches, are reliable. They are weather resistant and can survive intense heat and cold, moisture, and chemical exposure.

- Membrane switches are very much user-friendly. They are fairly straightforward to operate due to the tactile feedback built into the switches. This allows for the use of membrane switches with gloves or any other type of hand covering.

- Membrane switches are adaptable. They are easy to integrate into existing machinery due to their thin and small size, allowing for easy maintenance and cleaning.

- Membrane switches are simplistically designed, adopting a greatly utilitarian design (i.e., Only necessary features are integrated into membrane switch designs). This further adds to their overall adaptability.

- Membrane switches are cost competitive. Their simplistic design, as well as the simple materials they are made from, allows for mass production and therefore lower costs. Membrane switches overall cost competitiveness may explain why they are favoured over touch screen HMIs and why they are used by companies in many different sectors.

Conclusion

HMI technologies, despite being originally created many decades ago, remain relevant technologies. This is especially true of membrane switch technologies. For example, the industrial, medical, appliances, automotive, and energy sectors still regularly utilise membrane switch technologies.

Membrane switch technologies are, after all, reliable, user-friendly, safe, aesthetically pleasing, adaptable, and cost-efficient. There may still be a demand for these technologies. Should you and your company be interested in manufacturing membrane switches, Central Midori is there.

With more than 30 years of experience in membrane switches, Central Midori is here to help you design and manufacture your HMI solutions.